Special Design for Automatic Beverage Filling - PET bottled drinking water filling machine – LUYE Detail:

Product Description

This machines integrate washing, filling and capping into one unit, can be used for different kinds of fruit juices/tea hot drink production. With only a few parts changed, the machine can also be used for mineral water filling.The advanced micro-negative pressure filling technology is used in this machine. The filling is quick, steady and accurate. The beverage feedback system is well designed, the gas can be fed back separately, having no contact with beverage, reducing the second time pollution and oxidation. This machine can meet all the technical requirements for hot drink filling below 95. All filling valves and beverage conducting pipes can be cleaned, and the automatic washing interface CIP is designed in the machine. Before capping, the RO water washing device is used to wash the bottle mouth to keep mould away from the bottle mouth. Magnetic torque is used for screw capping, the power of screw capping can be adjusted step-less. Constant power can be used to screw the plastic caps. The human-machine-interface touch-screen, the most advanced PLC control and frequency changing technologies are used in this machine.

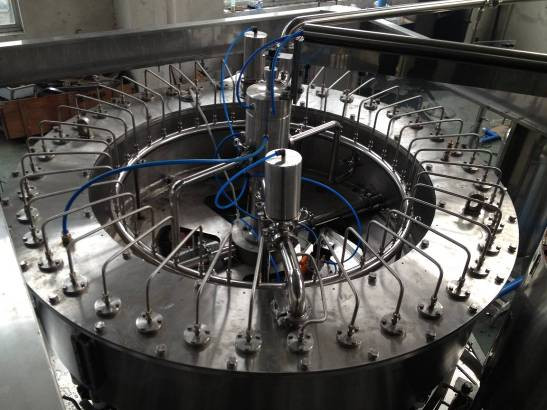

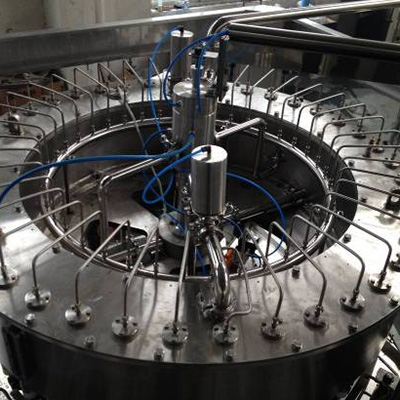

XGF40-40-12 water filling machine (3-in-1 type)

The bottle enters into the rinsing part of three-in-one machine through air conveyor. The gripper installed on the rotary disk catches bottle and turns it over 180 degrees and makes the bottleneck face ground. In the special rinsing area, the nozzle on the gripper sprays clean water to rinse inside part of the bottle. After rinsing and draining, the bottle turns over 180 degrees along the guide rail and make the bottleneck faces upwards. Then rinsed bottle is transferred to the filling part through poking bottle star-wheel. The bottle that enters into the filler is hold by neck holding plate. The filling valve acted by the cam can realize up and down. It adopts pressure filling way. The filling valve opens and begins filling when it moves down and touches the bottleneck, the filling valve move up and leave the bottleneck when it finishes filling, the full bottle is transferred to the capping part through hold neck transition poking wheel. The stop screwing knife holds the bottleneck, keeps bottle upright not rotating. The screw capping head keeps in revolution and autorotation. It can finish a whole capping course including catching, pressing, screwing, discharging through the action of the cam. The full bottle is transferred to bottle outlet conveyor to the next process through poking wheel. The whole machine is enclosed with windows, the height of enclosed window is higher than the peak of the 3 in 1 machine, in the bottom of the enclosed window has return air outlet.

Main Features

Main Specifications

(1) The equipment is featured by compact construction, perfect controlled system, convenient operation, and high automatic level.

(2) It only need to change the star-style wheel of spiral cover and arch board to change different bottles,

(3) The spare parts connected with the material are made of stainless steel, non process dead angle, easily cleaned.

(4) It adopts high speed filling valve, accurate liquid level and non liquid damage, to ensure filling industrial art.

(5) Sealing cap is adopted magnetic force torque device, to ensure the sealing quality, and not to damage the cap.

(6) It adopts high efficiency arranging cap system, which is characteristic with complete self control and safety device.

(7) It’s equipped with perfect over-load protecting device, which can protect effectively the equipment and operator.

(8) The controlling system is featured by producing speed control, missing cap detect, auto stop when bottles are stuck, production accounted.

(9) Main electric and pneumatic component are imported world famous brand.

(10) The machine is adopted advanced touch screen control; human machine dialogue operation is workable.

Product Parameter

(1) Working location: rinse 40, filler40, capper 12

(2) Production capacity: 18,000 BPH (300ml,600ml,1500ml)

(3) Air source pressure: 0.7MPa

(4) Air consumption: 1.0M3/min

(5) Rinsing water pressure: 0.2-0.25 MPa

(6) Rinsing water consumption: 2 t/h

(7) Filling method: pressure filling

(8) Host power: 3KW

(9) The total capacity: 4.5KW

(10) Voltage rating: 380V

(11) Dimension: 3430*2630*2700 (L×W×H)

(12) Weight: about 7500Kg

| Model | CGF8-8-3 | CGF14-12-4 | CGF18-18-6 | CGF24-24-8 | CGF32-32-10 | CGF40-40-12 |

| Capacity(500ML) | 2000-3000BPH | 3000-4000BPH | 6000-8000BPH | 8000-10000BPH | 12000-15000BPH | 16000-18000BPH |

| Floor area | 300㎡ | 400㎡ | 600㎡ | 1000㎡ | 2000㎡ | 2500㎡ |

| Total power | 100KVA | 100KVA | 200KVA | 300KVA | 450KVA | 500KVA |

| Opertor workers | 8 | 8 | 6 | 6 | 6 | 6 |

Product detail pictures:

Related Product Guide:

We believe in: Innovation is our soul and spirit. Quality is our life. Shopper need is our God for Special Design for Automatic Beverage Filling - PET bottled drinking water filling machine – LUYE, The product will supply to all over the world, such as: Washington, Nicaragua, Hongkong, We have been persisting in the business essence Quality First, Honoring Contracts and Standing by Reputations, providing customers with satisfying goods and service. Friends both at home and abroad are warmly welcome to establish everlasting business relations with us.

The goods we received and the sample sales staff display to us have the same quality, it is really a creditable manufacturer.

-

Factory best selling Automatic Bottle Juice Mac...

-

Best Price on Automatic Beverage Machine - car...

-

Factory wholesale Automatic Water Bottle Fillin...

-

OEM/ODM Supplier Beverage Bottle Filling Line -...

-

Good Quality Beverage Filling Packing Machine -...

-

China wholesale Bottle Juice Packing Machinery ...